Atmospheric Testing

Atmospheric Testing

This section provides an overview for understanding the atmospheric hazards and how you can test for them in the workplace.

Confined Space Atmospheric Testing

The presences of atmospheric hazards can be very complex and hard to monitor because they can be at various levels and locations and accumulate very rapidly into dangerous situations. The confined space must be tested for toxic, flammable and oxygen conditions. These conditions can be throughout the space and can change from minute to minute.

The tests for atmospheric hazards must be done at all areas and levels of the space before entry. Monitor the space continuously or retest periodically for as long as the space is occupied and as is appropriate for the hazard involved. The following are examples of atmospheric gases that may be located at different levels:

- Methane—0.6 times lighter than air—tends to accumulate in upper areas of the space, displacing good atmosphere with dangerous accumulation.

- Propane—1.5 times heavier than air—sinks and tends to accumulate in lower areas of the space, displacing good atmosphere with dangerous accumulation.

- Carbon Monoxide—approximately equal to air—can also accumulate in any or all areas throughout the space, displacing good atmosphere with dangerous accumulation.

The new legislation defines the type of work that can be completed in the confined space at various atmospheric levels.

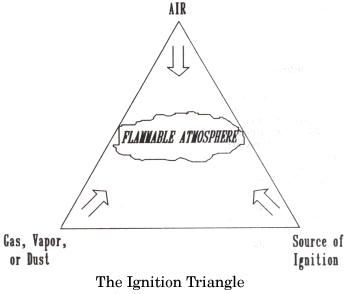

Flammable, Explosive or Combustible Atmosphere

Only inspection work may be done if the measured lower explosive limit (LEL) of an explosive or flammable gas or vapour is less than 25%, while cold work may be done if it is less than 10% of the LEL and hot work if less than 5% of the LEL.

Types of Work at Various Levels | ||

Old Legislation |

| New Legislation |

Not stated | Hot Work | <5% LEL |

<10% LEL | Cold Work | <10% LEL |

<50% LEL | Inspection Work | <25% LEL |

Toxic Atmospheres

Regulation 833/90 Control of Exposure to Biological or Chemical Agents has been designed to set safe limits to reduce employee exposure due to handling, storing and using of the controlled agents. The Act and Regulations require that employers take every precaution to protect their employees through personal protective equipment (gloves, goggles), engineering controls (ventilation) and safe work procedures. Regulation 833/90 has set guidelines for exposure levels for hundreds of biological and chemical agents. These are expressed in the following:

- IDLH (Immediately Dangerous to Life and Health) is the maximum airborne concentration of a biological or chemical agent beyond which a worker should be exposed to as it may pose a danger the health and safety of the workers.

- STEL (Short Term Exposure Limits) is the maximum airborne concentration of a biological or chemical agent beyond which a worker may be exposed to for a 15-minute period, four times per shift with a one-hour break between each exposure into the area.

- TWA (Time Weighted Average) is the maximum airborne concentration of a biological or chemical agent beyond which a worker can work an eight-hour shift for a 40-hour week without wearing protective respirators.

| IDLH | STEL | TWA |

Ammonia | 300 ppm | 35 ppm | 25 ppm |

Hydrogen Sulphide | 100 ppm | 15 ppm | 10 ppm |

Carbon Monoxide |

| 200 ppm | 25 ppm |

Toxic Atmospheres can come in two physical states and will be used to aid selecting the protective equipment used in confined space entry situation.

Non-particulates

- Gas - Natural gas begins seeping through the soil from a damaged metal line into the sewer piping system, or propane torch flames go out and gases are released.

- Vapours - Vapours are released from a degreasing solvent used to prepare a surface before welding. Some vapours are toxic as well as flammable.

Particulates

- Dusts—Dust from stored grains adhering to the sides of a storage tank is dislocated during repair work, creating an explosion hazard.

- Fumes—Fumes generated while heating an object up (welding, soldering) are released into the air.

- Mist—Mist generated while spraying a costing inside a tank creates a toxic and explosive atmosphere.

Oxygen-deficient Atmospheres

Activities or items in a confined space can affect the necessary levels of oxygen to perform the task and work actions. The level of oxygen found in normal atmospheric conditions is 20.9%. The dangerous oxygen atmosphere hazards can be divided into the following types:

- Oxygen Deficient: The level of oxygen decreases below 19.5%, and the employees will not have enough oxygen to perform the work activities. This decrease could be caused by the following:

- Hot work activities (welding, grinding, etc.).

- Oxidation of piping.

- Increased levels of toxic gases that push oxygen out of the space.

- Oxygen Enriched: The level of oxygen rises above 23%, making the space volatile and extremely flammable. This condition could be caused by the following:

- Oxygen tanks leaking into pit from storage areas.

- Welders’ torches leaking while the welders are performing work activities in the space.

Essential Skills for Atmospheric Testing

- Select appropriate instruments with correct sensors for the chemical agents.

- Electronic gas monitors.

- Read and understand testing equipment instructions.

- Verify proper functioning and reading of instruments.

- Use the instrument properly to get thorough and representative readings.

- Interpret and evaluate readings correctly.

Requirements for Atmospheric Reading Instruments

- Provide enough time for the instrument to respond properly.

- Provide regular care and maintenance.

- Have a competent operator use the equipment.

- Understand the limitations of the equipment.